I’m slightly surprised at that - I had kittens when I arrived to find the system showing a fault (and thus completely shut down) knowing that the previous few nights had been between -10° and -8°C but by that time I had figured out how to get into the maintenance settings so cleared the fault got the system running and prayed that there wasn’t a split pipe in the heat exchanger - which was actually fine, the pipes are fairly well lagged.

I believe these systems are often setup with a large thermal store to act as a buffer between the heat exchanger and circulation through the radiators - ours is 200l I think, having 200l of water sitting at 50-60°C is easily enough heat to keep the system frost free.

For us leaving the system powered up for 2-3 months is expensive but much less stress inducing; the long term plan is to get some remote control over the 'net - sadly the system is old enough that the manufacturer cannot supply the necessary bits so it is a DIY electronics project and I haven’t had the time to sort it out yet.

Yes, we’ve rented a property which had a fan & vents in the upper rooms, quite effective but I don’t think it would be easy to retro-fit; in any case the log burner is only a backup for the coldest weather.

Nearly 100% sure ours doesn’t - no way to get it in as far as I can see but it would seem to be an eminently sensible thing to do. I know that the ground sourced systems normally have antifreeze in the ground loop.

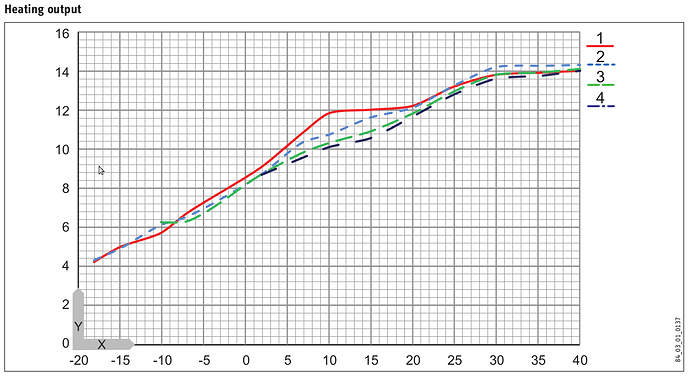

There are some quite complex graphs to look at during installation but when sizing a system you want to find a graph like this

Which shows heat output vs flow (line 1, red = 35°C flow temp and line 4=60°C) temperature and intake air temp, the model in this case is a Stiebel-Eltron WPL13S (now quite an old design) which is nominally 13kW output (I have the 16kW model).

From this we can see that the rated output is only actually available if the outside air is above about 22°, below that decent output is possible down to 10° but only at the lower flow temperature. If you have conventional radiators you need the flow temp as high as possible (a gas or oil system would have flow temps of 70° or so) but the air sourced systems do not work as well - in fact if you set the flow to 60° the system gives up the ghost a couple of degrees above freezing.

Turning the flow down to 55° (line 3) mitigates the performance at low air temps quite a bit but, while the system will produce some heat down to -10, it’s only kicking out half its rated output at that point though. Also 55° is a bit low for the hot water temp, so if you are using the heat pump for domestic hot water you need to make sure that there is an immersion heater and that the system is setup to do a pasteurisation cycle once a day - I’m a bit stuck as there is an immersion but not controlled by the system controller so I have the hot water set at 56° - just hot enough to kill legionella, with the flow a couple of degrees above that, not brilliant for efficiency but as low as I dare go.

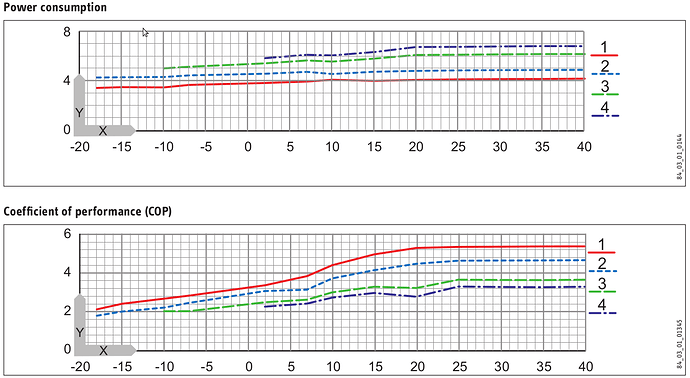

The other graphs to look at are power in vs heat output - in the case of the WPL13S these look like this

So, you can see the system is most efficient (COP of 5) for a flow temp of 35° and intake air of above 15° - basically when you don’t need it ![]() However there is still a COP of 2 at -10 with a flow of 55° Not great but better than just using electricity for heating.

However there is still a COP of 2 at -10 with a flow of 55° Not great but better than just using electricity for heating.