Many years ago I build a kitchen. I did so after drawing up a design and having several quotes, all of which we judged to be too high for our budget. It was my first big DIY project and it turned out quite well, and was commented favourably on years later when we sold the house.

Page forward several decades and I am considering doing the same thing in my new (to me) French house. This decision will be driven once again by a tight budget.

I would like to think my skills have improved somewhat and I certainly have more tools.

Several weeks ago when we got here, I bought some white melamine-finished ‘tablette’ from Leroy Merlin and build a very temporary ‘kitchen’ - about as big as two kitchen floor units, we refer to it as the camping kitchen - as a stop gap. Melamine-finished tablette is available in several sizes and it was my intention to build the carcasses (bodies) of the kitchen in this material and then either buy or make some nice shaker style doors and these would be paint finished.

One day, my partner accidentally left a damp cloth hanging over the edge of a shelf I had put in over the sink and the water seems to have gotten under the melamine facing strip on the edge of the shelf - the damage is not bad, it may well dry out, but if you look closely, you can see it.

So after all the background information above (sorry if I’ve rambled on too much), here’s my question. Is there a better material to use for the carcasses of the kitchen units - both floor units and wall units.

Perhaps technology has produced a better improved product in the 50 years since I built my DIY kitchen?

Any/all advice will be well received.

Years ago it was melamine covered particle board. Now its a laquered paper finshed even softer chipboard. Maybe by plywood and formica sheet?

The important word in this is carcase. Carcases are not designed to have anything more than the lightest contact with water, in other words just a wipe over. There is a better material to use than melamine faced chipboard (mfc), and that is high pressure laminate (hpl). The laminate has a much better resistance to bumps, scratches and liquids than mfc.

For a standalone shelf, I would definitely go for hpl. It is similar to the material you might use for a worktop. Examples here.

Price will be higher of course.

You might consider buying carcases in ready cut parts. I have successfully used them from this company who are UK based. I would guess similar exist in France.

I made the kitchen in our last UK house out of ‘proper’ beaded tongue and grooving (imported from Poland cos no-one seems to do any more in the UK. Then painted it in dead flat oil-based Farrow & Ball. Timber’s a lot more durable than melamine.

It is these days, old kitchen carcasses lasted 30-40 years, now you have to cut your fingernails before working on them or risk damage

Mark,

Did you have to go to Poland for the timber or can it be delivered to France?

I got it from a timber merchant in Blackburn, Lancashire who imported it, but I don’t know the name of the Polish source. I’ve just checked the Blackburn site and they longer list beaded tongue and grooving.

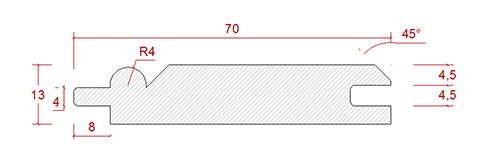

If I wanted some thing similar in France and couldn’t find it or router it myself I’d get a local carpenter to do it. The profile below is from a Swedish company, but it’s quite expensive.

It would surely be much cheaper to get it made locally, or simply opt for plain t&g without the bead - but I thnk the beaded version looks a lot classier!

Thanks, I just bought a new router so maybe I will give it a try when the time comes. ![]()

I’m still using the temporary kitchen I bought from a cheap and cheerful shop, I think it was Pico, in Germany at least 25 years ago. I saw it advertised in their weekly publicity and presumed it too would be cheap and cheerful but in fact it was surprisingly good, it has real oak veneer on the cupboard doors and I could choose the worktop, worktop height and handles. It was meant to be a temporary step for five years or so. It’s still going strong but I am considering giving it a cost of cream paint and having a new look.

Maybe buy ordinary t&g locally and do the beading with your new router.

I thought French ‘lambris’ has that but its too thin.

If you’re going to paint, it’ll be easier and cheaper to rout out MDF sheets they come in many sizes and thicknesses

Disagree as it would involve more routing and also IMO that sort of thing always looks bogus.

I agree, I’ve only seen that done once - about 8 years ago - and it didn’t look right.

I was thinking of thicker stuff - have removed a large amount of lambris cladding from our C14th house and was relieved to find original large chestnut beams and stone walls behind it.

However it makes excellent kindling for starting the log burner…